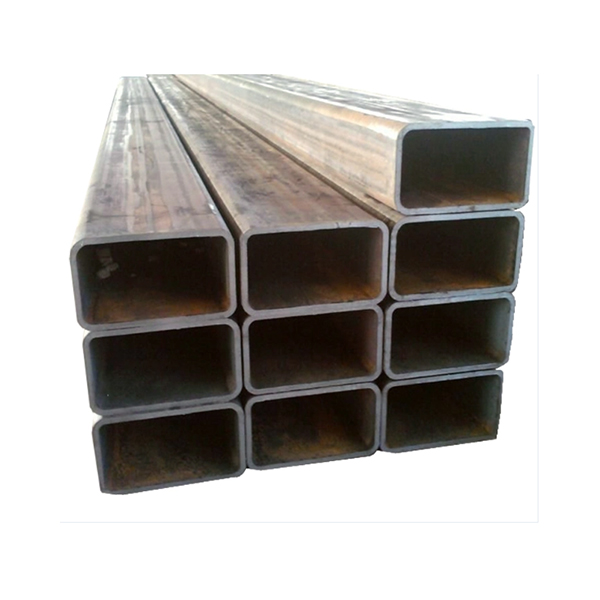

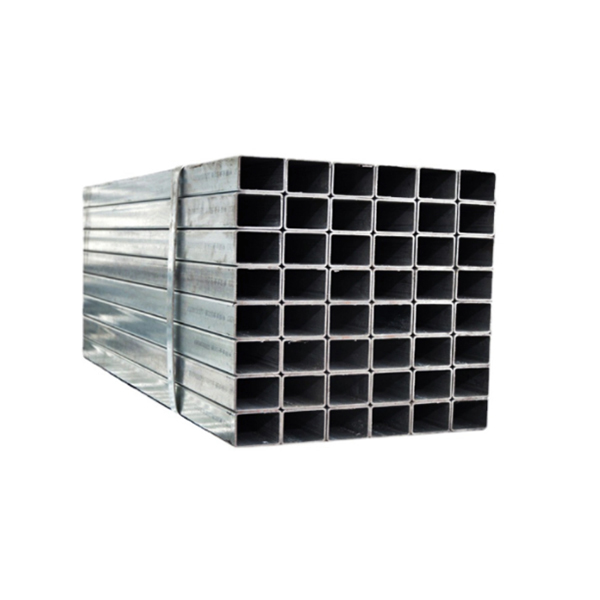

Bomba la chuma la mraba A513 kwa usafirishaji wa maji

Mirija ya mraba ya chuma ya A513, bomba la chuma la ukuta nene la mraba, bomba la chuma la mraba kubwa la kipenyo, bomba la chuma la mraba isiyo na mshono, bomba la chuma la mraba la aloi ya chini, bomba la chuma la mraba 135*135*10, bomba la chuma la mnara wa crane, bomba la chuma la aloi ya chini ya Q345B, 20 # bomba la chuma la mraba isiyo imefumwa

Mirija ya mraba ya chuma ya A513, Kama jina linamaanisha, ni umbo la mraba la bomba, aina nyingi za nyenzo zinaweza kuunda bomba la mraba, kati yake, nini cha kutumia, wapi kutumia, bomba nyingi za mraba hadi bomba la chuma. kwa wengi, hasa kwa ajili ya miundo mraba tube, mapambo mraba tube, jengo mraba tube na kadhalika.

Mirija ya Mraba ya Chuma ya A513, Ni jina la mirija ya mraba, ambayo ni mirija ya urefu sawa.Inafanywa kwa chuma cha strip baada ya usindikaji na rolling.Kwa ujumla, ukanda huo haujapakiwa, kusawazishwa, kukatwa na kuunganishwa kwenye bomba la pande zote, ambalo huvingirishwa kwenye bomba la mraba na kisha kukatwa kwa urefu unaohitajika.Kawaida vijiti 50 kwa pakiti.

A513 Chuma Square neli, Kuna pointi imefumwa na weld, imefumwa mraba tube ni imefumwa tube extrusion ukingo.Bomba la chuma la mraba, bomba la chuma la mraba nene la ukuta, bomba la chuma la mraba kipenyo kikubwa, bomba la chuma la mraba lisilo na mshono, bomba la chuma la aloi ya chini, bomba la chuma la mraba 135*135*10, bomba la chuma la mraba la crane, Q345B bomba la chuma la aloi ya chini, 20 # bomba la chuma la mraba lisilo imefumwa

1. Uchambuzi wa utendaji wa kielelezo wa zilizopo za mraba - plastiki

Plastiki inahusu uwezo wa nyenzo za chuma kuzalisha deformation ya plastiki (deformation ya kudumu) bila uharibifu chini ya mzigo.

2. Uchambuzi wa index ya utendaji wa tube ya mraba - ugumu

Ugumu ni kipimo cha jinsi nyenzo ya chuma ilivyo ngumu au laini.Kwa sasa, njia inayotumiwa zaidi ya kuamua ugumu katika uzalishaji ni njia ya ugumu wa indenter, ambayo ni kutumia sura fulani ya kijiometri ya kichwa cha ndani chini ya mzigo fulani kwenye uso wa vifaa vya chuma vilivyojaribiwa, kulingana na kiwango cha indenter kuamua thamani ya ugumu wake.

Mbinu zinazotumiwa kwa kawaida ni ugumu wa Brinell (HB), ugumu wa Rockwell (HRA, HRB, HRC) na ugumu wa Vickers (HV) na mbinu nyinginezo.

3. Uchambuzi wa index ya utendaji wa tube ya mraba - uchovu

Nguvu, kinamu, na ugumu uliojadiliwa hapo juu ni viashiria vya sifa za mitambo ya metali chini ya upakiaji tuli.Kwa kweli, sehemu nyingi za mashine zinaendeshwa chini ya mizigo ya mzunguko, na uchovu unaweza kutokea chini ya hali hizi.

4. Uchambuzi wa ripoti ya utendaji wa bomba la mraba - ugumu wa athari

Mzigo unaofanya kazi kwenye sehemu kwa kasi kubwa huitwa mzigo wa athari, na uwezo wa chuma kupinga uharibifu chini ya mzigo wa athari huitwa ushupavu wa athari.

5. Uchambuzi wa fahirisi ya utendaji wa bomba la mraba - bomba la chuma la mraba lenye nguvu, bomba la chuma la mraba lenye kipenyo kikubwa, bomba la chuma la mraba lisilo na mshono, bomba la chuma la aloi ya chini, bomba la chuma la mraba 135*135*10, bomba la chuma la mraba la crane. , Q345B aloi ya chini ya mraba bomba chuma, 20# imefumwa mraba chuma bomba

Nguvu ni uwezo wa nyenzo za chuma kupinga kushindwa (deformation ya plastiki nyingi au fracture) chini ya upakiaji wa tuli.Kutokana na hali ya upakiaji katika mfumo wa kukaza, compression, bending, shearing, hivyo nguvu pia kugawanywa katika tensile nguvu, compressive nguvu, bending nguvu, SHEAR nguvu na kadhalika.Mara nyingi kuna uhusiano fulani kati ya nguvu mbalimbali, na nguvu ya mkazo kwa ujumla hutumiwa kama kiashirio cha msingi zaidi cha nguvu.

Ukubwa

| Ukubwa kwaInch (kipenyo) | Unene | Ukubwa kwa MM (kipenyo) | Unene |

| inchi | inchi | mm | mm |

| 1/2" x 1/2" | 0.065" | 16mm×16mm | 0.4mm ~ 1.5mm |

| 3/4" x 3/4" | 0.049" | 18mm×18mm | 0.4mm ~ 1.5mm |

| 0.065" | 20mm×20mm | 0.4mm ~ 3mm | |

| 0.083" | 22mm×22mm | 0.4mm ~ 3mm | |

| 0.120" | 25mm×25mm | 0.6mm ~ 3mm | |

| 1" x 1" | 0.049" | 30mm×30mm | 0.6mm ~ 4mm |

| 0.058" | 32mm×32mm | 0.6mm ~ 4mm | |

| 0.065" | 34mm×34mm | 1mm ~ 2mm | |

| 0.072" | 35mmx35mm | 1 hadi 4 mm | |

| 0.083" | 38mm×38mm | 1 hadi 4 mm | |

| 0.095" | 40mm×40mm | 1mm ~ 4.5mm | |

| 0.109" | 44mm×44mm | 1mm ~ 4.5mm | |

| 0.120" | 45mm×45mm | 1 hadi 5 mm | |

| 1 1/8" x 1 1/8" | 0.035" | 50mmx50mm | 1 hadi 5 mm |

| 0.049" | 52mm×52mm | 1 hadi 5 mm | |

| 0.065" | 60mmx60mm | 1 hadi 5 mm | |

| 0.109" | 70mmx70mm | 2 hadi 6 mm | |

| 0.120" | 75mmx75mm | 2 hadi 6 mm | |

| 1 1/4" x 1 1/4" | 0.049" | 76mmx76mm | 2 hadi 6 mm |

| 0.065" | 80mm×80mm | 2 hadi 8 mm | |

| 0.072" | 85mm×85mm | 2 hadi 8 mm | |

| 0.083" | 90mm×90mm | 2 hadi 8 mm | |

| 0.109" | 95mm×95mm | 2 hadi 8 mm | |

| 0.120" | 100mm×100mm | 2 hadi 8 mm | |

| 0.135" | 120mm×120mm | 4 hadi 8 mm | |

| 0.156" | 125mm×125mm | 4 hadi 8 mm | |

| 0.188" | 130mm×130mm | 4 hadi 8 mm | |

| 1 1/2" x 1 1/2" | 0.049" | 140mm×140mm | 6 hadi 10 mm |

| 0.065" | 150mm×150mm | 6 hadi 10 mm | |

| 0.072" | 160mm×160mm | 6 hadi 10 mm | |

| 0.083" | 180mm×180mm | 6mm ~ 12mm | |

| 0.109" | 200mm×200mm | 6 hadi 30 mm | |

| 0.120" | 220mm×220mm | 6 hadi 30 mm | |

| 0.140" | 250mm×250mm | 6 hadi 30 mm | |

| 0.188" | 270mm×270mm | 6 hadi 30 mm | |

| 0.250" | 280mm×280mm | 6 hadi 30 mm | |

| 1 3/4" x 1 3/4" | 0.065" | 300mm×300mm | 8mm ~ 30mm |

| 0.083" | 320mm×320mm | 8mm ~ 30mm | |

| 0.095" | 350mm×350mm | 8mm ~ 30mm | |

| 0.109" | 380mm×380mm | 8mm ~ 30mm | |

| 0.120" | 400mm×400mm | 8mm ~ 30mm | |

| 0.188" | 420mm×420mm | 10 hadi 30 mm | |

| 2" x 2" | 0.049" | 450mm×450mm | 10 hadi 30 mm |

| 0.065" | 480mm×480mm | 10 hadi 30 mm | |

| 0.083" | 500mm×500mm | 10 hadi 30 mm | |

| 0.109" | 550mm×550mm | 10 hadi 40 mm | |

| 0.120" | 600mm×600mm | 10 hadi 40 mm | |

| 0.145" | 700mmx700mm | 10 hadi 40 mm | |

| 0.165" | 800mm×800mm | 10 hadi 50 mm | |

| 0.188" | 900mm×900mm | 10 hadi 50 mm | |

| 0.250" | 1000mm×1000mm | 10 hadi 50 mm | |

| 0.312" | |||

| 2 1/4" x 2 1/4" | 0.188" | ||

| 0.250" | |||

| 2 1/2" x 2 1/2" | 0.083" | ||

| 0.109" | |||

| 0.120" | |||

| 0.188" | |||

| 0.250" | |||

| 0.312" |

| 3" x 3" | 0.083" |

| 0.120" | |

| 0.188" | |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 3 1/2" x 3 1/2" | 0.120" |

| 0.188" | |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 4" x 4" | 0.083" |

| 0.120" | |

| 0.156" | |

| 0.188" | |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 0.500" |

| 4 1/2" x 4 1/2" | 0.188" |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 5" x 5" | 0.188" |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 0.500" | |

| 6" x 6" | 0.188" |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 0.500" | |

| 0.625" | |

| 7" x 7" | 0.188" |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 0.500" | |

| 0.625" |

| 8" x 8" | 0.188" |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 0.500" | |

| 0.625" | |

| 9" x 9" | 0.188" |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 0.500" | |

| 0.625" | |

| 10" x 10" | 0.188" |

| 0.250" | |

| 0.312" | |

| 0.375" | |

| 0.500" | |

| 0.625" | |

| 12" x 12" | 0.250" |

| 0.312" | |

| 0.375" | |

| 0.500" | |

| 0.625" | |

| 14" x 14" | 0.312" |

| 0.375" | |

| 0.500" | |

| 0.625" | |

| 16" x 16" | 0.312" |

| 0.375" | |

| 0.500" | |

| 0.625" |

Muundo wa Kemikali wa Nyenzo

| Daraja | kipengele | C | Mn | P | S |

| ASTM A500 Gr.b | % | 0.05%-0.23% | 0.3%-0.6% | 0.04% | 0.04% |

| Acc.to EN10027/1 | Acc.to EN10027/2 | Upeo wa C% (WT ya Kawaida(mm) | Si% max | Mn% max | Upeo wa P% | Upeo wa S%. | Upeo wa N% | |

| na IC 10 | ≤ 40 | |||||||

| S235JRH | 1.0039 | 0.17 | 0.20 | - | 1.40 | 0.045 | 0.045 | 0.009 |

| S275JOH | 1.0149 | 0.20 | 0.22 | - | 1.50 | 0.040 | 0.040 | 0.009 |

| S275J2H | 1.0138 | 0.20 | 0.22 | - | 1.50 | 0.035 | 0.035 | - |

| S355JOH | 1.0547 | 0.22 | 0.22 | 0.55 | 1.60 | 0.040 | 0.040 | 0.009 |

| S355J2H | 1.0576 | 0.22 | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | - |

Sifa za Mitambo za Nyenzo

| Daraja | Nguvu ya Mavuno | Nguvu ya Mkazo | Kurefusha |

| A500.Gr.b | 46 ksi | 58 ksi | 23% |

| A513.GR.B | 72 kama | 87 kama | 10% |

| Kawaida | Nguvu ya Mavuno | Nguvu ya Mkazo | Min.elogation | Asilimia ndogo ya mali | ||||||||

| Acc.to EN10027/1na IC 10 | Acc.to EN10027/2 | WTmm ya kawaida | WTmm ya kawaida | Muda mrefu. | Msalaba | Jaribio la halijoto°C | Thamani ya wastani ya athari | |||||

| ≤16 | >6 | >40 | <3 | ≤3≤65 | WTmm ya kawaida | |||||||

| ≤65 | ≤65 | ≤40 | >40 | >40 | ≤65 | |||||||

| ≤65 | ≤40 | |||||||||||

| S253JRH | 1.0039 | 235 | 225 | 215 | 360-510 | 340-470 | 26 | 25 | 24 | 23 | 20 | 27 |

| S275JOH | 1.0149 | 275 | 265 | 255 | 410-580 | 410-560 | 22 | 21 | 20 | 19 | 0 | 27 |

| S275J2H | 1.0138 | 275 | 265 | 255 | 430-560 | 410-560 | 22 | 21 | 20 | 19 | -20 | 27 |

| S355JOH | 1.0547 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | 0 | 27 |

| S355J2H | 1.0576 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | -20 | 27 |

Vipimo Sawa

| EN 10210-1 | NF A 49501 NF A 35501 | DIN 17100 DIN 17123/4/5 | BS 4360 | UNI 7806 |

| S235JRH | E 24-2 | St 37.2 | - | Fe 360 B |

| S275JOH | E 28-3 | St 44.3 U | 43 C | Fe 430 C |

| S275J2H | E 28-4 | St 44.3 N | 43 D | Fe 430 D |

| S355JOH | E 36-3 | St 52.3 U | 50 C | Fe 510 C |

| S355J2H | E 36-4 | St 52.3 N | 50 D | Fe 510 D |

| S275NH | - | Mt E 285 N | - | - |

| S275NLH | - | TSt E 285 N | 43 EE | - |

| S355NH | E 355 R | Mt E 355 N | - | - |

| S355NLH | - | TSt E 355 N | 50 EE | - |

| S460NH | E 460 R | Mt E 460 N | - | - |

| S460NLH | - | TSt E 460 N | 55 EE | - |

- barua ya kuzuia "S" inamaanisha "CHUMA KWA MAOMBI YA MUUNDO"

- figure inayofuata inamaanisha minim.thamani ya mavuno inahitajika kwa unene wa ukuta ≤16 mm

- "J2" inamaanisha thamani ya jaribio la athari -20° C dakika.27 joule

- barua ya kuzuia "H" ina maana "SEHEMU SHIFU".

Onyesho la Bidhaa